| 1. | ||

| 2. | ||

| 3. | ||

| 4. | ||

Electrical Properties of Polypropylene Composites with a- Fе2О3 Filler Heat-Treated in Vacuo

F. I. Ahmadov, M. B. Huseynova, M. Y. Huseynova, A. D. Guliyev,

R. A. Jafarova

Institute of Petrochemical Processes of National Academy of Sciences of Azerbaijan, Khojaly Avenue, Baku, Azerbaijan

Email address

(F. I. Ahmadov)

(F. I. Ahmadov) Citation

F. I. Ahmadov, M. B. Huseynova, M. Y. Huseynova, A. D. Guliyev, R. A. Jafarova. Electrical Properties of Polypropylene Composites with a- Fе2О3 Filler Heat-Treated in Vacuo. Engineering and Technology. Vol. 3, No. 1, 2016, pp. 26-29.

Abstract

The electrical properties of composites based on polypropylene (PP) filled with a- Fе2О3 heat-treated in vacuo were studied in this article. It was found that the electrical properties of composites depend on as the amount of filler as the conditions of treatment of the filler, which is reflected in the temperature dependence of the electrical conductivity and the frequency dependence of the dielectric constant (conductivity) and dielectric loss. It was established that by changing both the quantity and the processing conditions of the filler one can control electro-physical properties of the stated composite materials.

Keywords

Dielectric Composite, Polypropylene, Metal Oxides, Polyolefins, Filler, Hematite

1. Introduction

The polymeric composite materials are widely used in the various fields of the human activity. Their range covers a wide field from the household appliances to the special-purpose machinery. We can specify that the materials consisting of polymer composites, showing electret properties, are used in the electret microphones, dosimeters, pressure sensors, sign phones, electromechanical transducers etc.

The following unites such as head dome shells, hub fairing, instrument frames, air ducts, shells, pipes, power profiles for space telescopes and satellites, thermal panels of thermal control systems, thermal barrier coatings for spacecraft, etc. manufactured from polymer composites in the rocket and space technology.

Polymeric composite materials are also used in the production of artificial blood vessels with the purpose to reduce the blood thrombosis, of packaging material to increase the storage life of products, of the anticorrosive insulation coatings.

In connection with the properties of composite materials listed above, to get multi-functional polymer composites of different composition (with fillers such as metal oxides with different amount) and study of ifluence of their structure and properties of the polymer matrix and filler, of physico-chemical interaction between them, as well as on the electrical properties composites in general is an urgent task.

When producing the composite materials with these properties, there are several ways to change the electrical (including electret, sensory and so on) properties of polymers, for instance, adding the dispersed fillers to the volume of the polymer [1], modification of the polymer surface by different methods [2, 3,10] mixing various polymers [4], etc.

The uniqueness of the composite materials is that that it is possible to design the material in advance so as to give to the product the properties required for a particular field of application.

Since the electrical properties of the material are uniquely related to its dielectric properties, then having studied the patterns of these characteristics of polymer composite materials and how to manage these properties we can extend the range of use of these materials.

A large number of theoretical and experimental studies were dedicated to the study of these issues in the scientific literature, however, there were no any systematic patterns of results and linking methods of obtaining, structure and physico-chemical characteristics of such complex systems [5].

Based on those tated above, there were studied electrical and dielectric properties of polypropylene composites with α-Fe2O3 filler, heat-treated in vacuum, in the present work.

2. The Study Object

In the capacity of matrix to produce composite materials there had been selected nonpolar SC (semiconductor) with the follwoing physical properties such as 04П, εпп=2.2, tgδпп=3*10-4, ρvпп=1017Ом*м. In the capacity of the connecting material there was selected α-Fe2O3 semiconductor. The ferric oxide (III) with a particle sized as 25micron formed crystals of cubic syngony, space group F d3m, cell parameters a = 0,844nm, Z = 8, with the dielectric parameters: εα-Fe2O3=14.2, tgδα-Fe2O3=4*10-4, ρvα-Fe2O3=108Оm*m. This oxide is used in production of special electrodes.

3. Research Methods

Heat treatment of α-Fe2O3 filler was conducted at the temperature of 893K in a low vacuum (~ 0,01atm.) to a further cooling at a constant rate.

Samples of the composites were prepared by powder compaction of the filler and polymer blends, mixed to uniformity in a ball mill.

The sample is placed in a heated press and under the pressure of 10 MPa and kept for 5 minutes at the melting temperature of the polymer. After pressing the melt composite being between the layers of aluminum foil is subjected to rapid cooling at 273K in accordance with GOST 12019-66. The thickness of the sample is determined by an electronic micrometer.

Measurement of electrical capacitance of "C" samples was conducted by the means of E6-13A Teraohmmeter. Temperature dependence of the dielectric parameters ε and tgδ samples were determined with a rise in temperature at a linear velocity 2grad / per min. using E7-20 measuring immittance.

The diffraction patterns of X-ray diffraction instrument analysis were made by help of Emperyen, PANanalitical of EA series (Netherlands).

The dispersity of the samples was determined by Hitachi S3400 electronic microscope.

4. Experimental Part

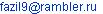

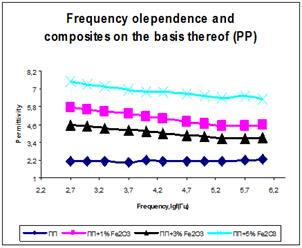

Study results were presented in Figures (1-4). As its is seen from the frequency dependence, the values of the sample’s dielectric constant (Figure 1) with the % α- α-Fe2O3 filler are ranged from 0.0461 to 0.0675. A further increase in the amount of filling results in reducing both the maximum value of the dielectric constant of samples and the scope of its changing and shall be 0.0375 - 0.04. When the amount of the filler is 5ob.% the maximum value of the dielectric constant shall be 0.04.

As we know from the literary sources [1], there is a area with a certain amount of filler, when the interaction between the atoms and molecules of the filler exceeds the interaction between the atoms and molecules of the polymer and polymer with a filler. Along with it the conductivity of the composite is determined by the properties of the filler which is accompanied by an increase in the values of electrical conductivity.

In our experiment these conditions are realised for the composite filled with 1%-α-Fe2O3. Manifestation of the small peak dependency at the high area (Figure 1), apparently is due to the fact that at low frequencies, the composite polarization becomes insignificant. However, when frequency values are high the number of cycles per unit time of polarization increases, and thus, the dielectric constant of the composite is increased [6, 7, 9].

Fig. 1. Dependence of dielectric penetrability of composites РР + α-Fe2O3 from the frequency.

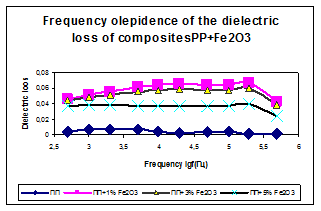

Fig. 2. Diffraction pattern of α-Fe2O3 powders heat-treated at the low vacuum.

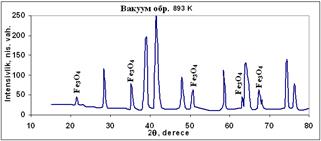

Fig. 3. Temperature dependence of resistivity of РР + α-Fe2O3 composites.

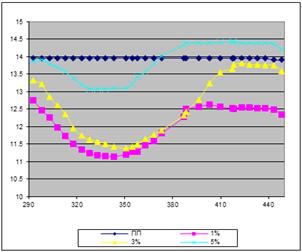

Fig. 4. Frequency dependence of tangent of angle of dielectric loss of РР + α-Fe2O3 composites.

This fact gives us grounds to assume that the content of 1% of filling results in the noticeable change as in the supramolecular structure as in appearance on the border of polymer - filler of the extra charged particles.

As confirmation of those noted above, our hypothesis based on that the regime (the atmosphere and low vacuum) are different by the oxygen content which should be reflected in the electrical properties of the composite which was produced by X-ray analysis of the heat-treated α-Fe2O3 powder (Fig. 2). It is seen from the diffraction patterns that the sample is thermally treated under low vacuum observed reflections corresponding phase of Fe3O4. Results that we got by way of experiments match with the results of the authors [8] in the matter that the heat treatment of the α-Fe2O3 oxide under reduced pressure followed by a partial transfer of oxide to the magnetite (Fe3O4).

As further confirmation of the results obtained there were studied the temperature dependence, the resistivity of РР + α-Fe2O3 samples presented in the Figure 3.

By the type of dependence the resistivity change may be divided into the low and high temperature parts. As the dependence on low-temperature area (290-330K) shows, the electrical conductivity of all samples increases. In this case the composite with 1% filler has the highest value. During studies conducted by us there was found that the increase in the electrical conductivity in the low temperature range is associated with the softening of the amorphous part of the polymer [5-7,9]. A further increase in temperature (330-345K) is accompanied by the stabilization of electrical conductivity at high temperatures (345-400K), along with what the rise of resistance, which later stabilized. But the stabilization of composites with different amounts of filler shows other character. So the composites’ resistivity stabilization begins at 1% vol. 3%vol, 5% vol. and corresponds to values: 12.6, 13.8, 14.5.

In figure 4 there is shown the frequency dependence of the dielectric loss of PP + α-Fe2O3 composites, which demonstrates the independence of this parameter on the frequency but a composite with 5%vol. filler has a maximum value of tgδ = 8.

The results obtained with respect of the electrical conductivity coincide with the conclusions derived from X-ray measurements of dielectric constant and which proves the correctness of the assumption that there is a certain amount of filler, when the interaction between the atoms and molecules of the filler are superior interaction between the atoms and molecules of the polymer with the polymer and filler which It reflected both in the electrical, and the dielectric characteristics.

So, our studies create opportunities to ensure that the basis of the results obtained in the future, it will be possible to develop more sensitive semiconductor composites [2, 7].

References