The Invention of Household Automatic Tofu Machine

Siping Li, Jiajia Gan, Pei Feng*, Chongchang Yang

Engineering Research Center of Advanced Textile Machinery, Ministry of Education, Donghua University, Shanghai, China

Email address

(Pei Feng)

*Corresponding author

Citation

Siping Li, Jiajia Gan, Pei Feng, Chongchang Yang. The Invention of Household Automatic Tofu Machine. Engineering and Technology. Vol. 3, No. 3, 2016, pp. 61-66.

Abstract

Tofu has a long history, special flavozrs, high nutritional value and physiology functions as a traditional Chinese food. In this work, a new automatic tofu machine was designed to product tofu more conveniently at home. This household automatic tofu machine is developed and presented on the basis of the existing soybean milk machine. It can achieve the automation operation including squatting, broken uncongealed tofu, pressing and other actions using mechanical and electrical control scheme. The household automatic tofu machine not only can make soy milk, uncongealed tofu, plaster tofu, lactone tofu, but also can achieve the function of self-cleaning.

Keywords

Household Tofu Machine, Electromechanical Control, Automation, Single Chip Microcomputer

1. Current Research Status of Household Tofu Machine

Tofu is always served on the table of Chinese as a delicacy. It has a long history for its abundant nutrition and support for human health [1]. It contains many micro elements necessary to the human body, including calcium, phosphorus, potassium, and iron. Tofu also contains sugar, vegetable oil and the rich high quality protein, because of which it is called ‘the meat of plant’. Soybean has a high nutritional value because it can enhance the protein digestibility. Whole grain of cooked soybean digestion rate was 65%, made from soybean milk could reach 85% after soybean milk made from soy protein degeneration happened after solidification, digestion and absorption rate of up to 92% - 98% [2]. So, for Asian immigrants, both soy-milk and tofu, are very popular as a staple of the human diet [3-5].

As meat production costs escalate, the demand for the cheaper vegetable protein will increase [6]. Besides, people want to make their own food at home, partially for safety reasons. As the most common kind of bean products, soybean-milk has been in China since about 25~220 AD [7]. And household soybean-milk machine has fully developed [8-15]. But for automatic tofu machines, at present, most of them have huge volume and are built for mass production for enterprises instead of family use. At the same time, there are few household tofu machines appearing on the small household appliances market. Shenzhen Tang Intelligent Control Co., Ltd. launched the first smart tofu machine in the international market. It is essentially an automatic Soybean Milk machine, because it requires staff to manually complete the production of tofu, such as discharging slurry stirred coagulant, pressing tofu, filtering out excess water and so on. It has not achieved a fully automatic production process of household tofu machine until now.

2. Mechanical Part Design of Household Automatic Tofu Machine

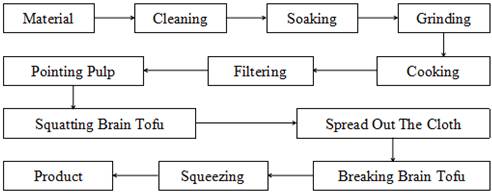

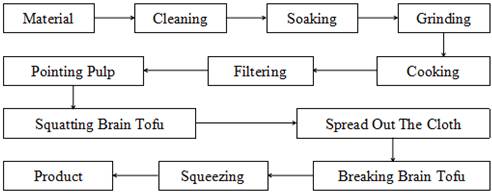

Fig. 1. The traditional production process of tofu.

Figure 1 shows the process of household automatic tofu machine which is based on the soybean-milk machine already in the market. It will perform the tofu-made automatic including grinding, cooking, filtering, point pulp, squatting uncongealed tofu and squeezing.

2.1. The Design of Pulping and Cooking Device

Nowadays, the household soybean-milk machine has enough function to deal with this part of design requirement[16]. The basic working process:

(1) put the soaked beans into the household soybean-milk machine with water as needed.

(2) heat the pulping.

(3) cook the soybean-milk and blowing (cooled properly).

2.2. The Design of Automatic Pulp-inlet Device

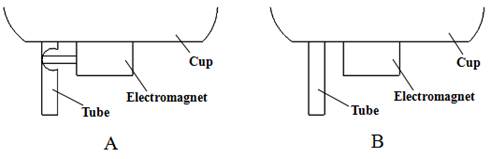

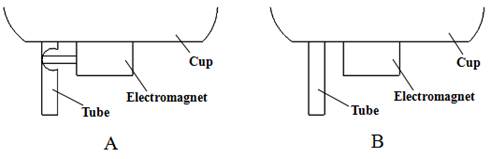

Automatic pulp-inlet device means put the cooked soybean-milk into the next step. It uses electromagnet to control this device. Figure 2 shows that there is a tube installed at the pulp-outlet. It uses the electromagnet to pressure or relax the tube in order to control the soybean-milk out or not.

Fig. 2. Automatic pulp-inlet diagram.

At beginning, the water or the soybean-milk cannot blow out because the tube is against by the armature from the electromagnet. It makes the pulping and cooking action come true (figure A). After the coil energized, iron core and armature from the electromagnet are magnetized. It generates opposite polarity magnet. When the electromagnetic force is greater than counterforce from the bounce, the armature moves and the soybean-milk comes out after the tube relaxed. Then step into the next stage (figure B).

2.3. The Design of Automatic Dasher

Dasher is used for stirring the water, soybean-milk and the coagulator. The latter is called pointing pulp which used in the traditional tofu production. It makes the soybean protein from sol to gel. The speed of stirring and the time are very important, they have direct relationship when it adds the coagulator [2, 17, 18]. It means the stirring quicker, the less used coagulator and quicker speed of the solidification, and vice versa [19-24].

The whole process is accomplished by a mixing box. There are two different sizes stirrer in the box which is controlled by micro motor. The small one is used to dilute the coagulator, another one is used to point pulp. At the meantime, the mixing box has the scale and temperature sensor to control the whole process.

2.4. The Design for the Automatic Breaking Uncongealed Tofu Device

After the pointing pulp, soybean-milk and the coagulator need stew for about 20 minutes. It makes the interwoven net style of the protein fastness and the bean curd jelly with tenacity [2]. We call this action--squatting uncongealed tofu.

After the squatting uncongealed tofu, the protein contains a lot of water. Before the product comes out, it needs to break uncongealed tofu according to the requirements of tenacity and specialty [25]. It puts the jellied bean curd in a vessel which has tofu filter cloth. There are some circular holes at the bottom of the vessel which uses to discharge water.

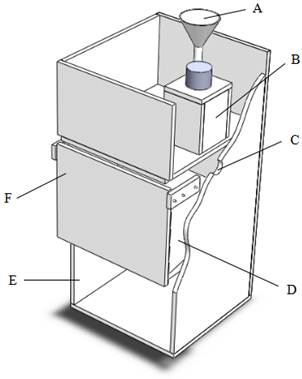

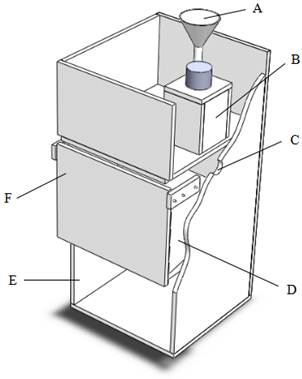

Fig. 3. Soybean-milk box diagram.

A-funnel; B-mixing box; C-pulp inlet; D-squatting uncongealed tofu box; E-storage box; F-shutter

Figure 3 shows the coagulator mixed liquor go through the funnel. After stirred, it comes to the squatting uncongealed tofu box for the following process. The shutter is controlled by the electromagnet which implement the breaking uncongealed tofu stage.

2.5. The Design for the Automatic Squeezing Device

The water in the solid bean curd flower mixture need be squeezed to meet the demand of the quality. Uncongealed tofu, brine tofu, gypsum tofu and lactone tofu don’t need to be squeezed.

The more squeezed force, the more water out, and the less water in. From the test, when the production is under the 500g, it uses the plaster tofu and the brine tofu as the reference and use different force to squeeze them. It can draw a conclusion that the squeezing force is about 2.5N ~5N.

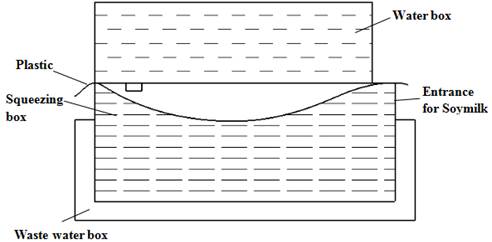

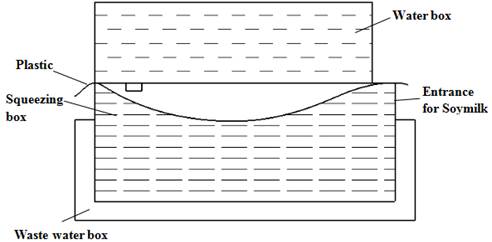

Figure 4 shows there is a water box above the squeezing box. It contains about 250g-500g water. When the small valve open, the water flow into the fixture plastic. The water will go through the holes which in the lower shutter and the lateral plate into the waste water box. The character of the water makes the squeezing force become balanced and the tofu smoothly. It approximates to the traditional manual squeezing.

Fig. 4. The schematic diagram of water squeezing.

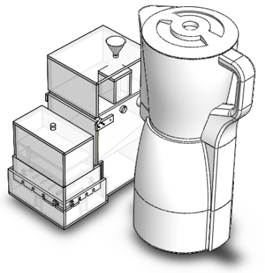

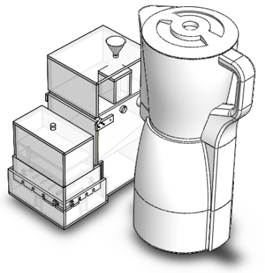

Figure 5 shows the invention of the household automatic tofu machine. It can performs the automatic tofu-made. It can made the soybean-milk, jellied bean curd, brine tofu, plaster tofu so on. It also has many advantages such as small volume, product moderation and easy-operation. From the entity testing, it meets the anticipated requirements.

Fig. 5. Household automatic tofu machine.

3. Control System Design of Main Function Module

3.1. The Design of Control System of Cookinging and Pulping

Soybean crushing at room temperature will produce two types of enzymes, it is not conducive to the human body to absorb nutrients. And these two enzymes will break down at 86°C. At the same time, milk protein and other nutrients can be more fully overflow, and emulsification effect will be better. Thus, it is necessary to heat before pulping.

Fig. 6. Control system of the heating pipe and beating motor with SCM.

The principle of control system is as follows: Single Chip Microcomputer issues temperature reading command to temperature sensor, and it will compare to the preset temperature after obtaining the temperature and determine the working status of the heating pipes. SCM through the driver chip ULN2003 will control the relay energized and de-energized to control heating and beating motor on or off.

3.2. The Design of Control System of Discharge Soybean Milk

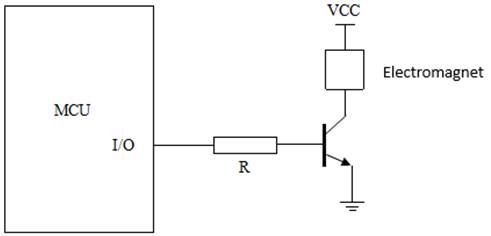

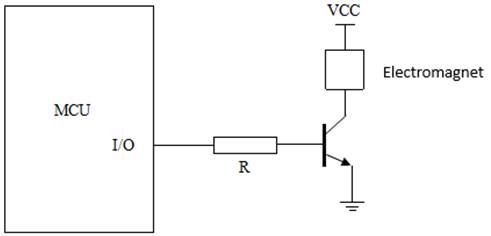

Using single-chip microcomputer control electromagnet to discharge soybean milk. The electromagnet is a kind of electrical apparatus used to accomplish the expected action by using the electromagnetic suction generated by the current carrying coil. It is a kind of electromagnetic device which can convert electrical energy into mechanical energy.

Fig. 7. Control of the electromagnet with SCM.

In the initial state, since the electromagnet is not energized, the spring tensions bar so that the hose is squeezed and milk cannot flow out. When the electromagnet is powered up, the electromagnetic suction forces the spring to relax the pressure bar, and the hose is released, the soybean milk discharging is realized. Electromagnet energized or de-energized is determined by the SCM via I/O port. SCM control I/O port output high level, the transistor base coupled with a positive bias, then the transistor is turned on, the electromagnet is energized. Similarly, SCM control I/O port output low level, the solenoid is de-energized.

3.3. The Design of Control System of Automatic Dasher

The stirring device has two functions, one is to stir the mixture of coagulant and water, the other is to stir the mixture of coagulant and soybean milk, realize curding. While adding the coagulant and stirring along the same direction at the same time, it not only need the good coagulant adding amount but also the slurry temperature. Usually the temperature of the milk is between 70°C~90°C. Temperature sensor can be used to control the temperature of the milk and achieve the desired temperature, the milk is put out.

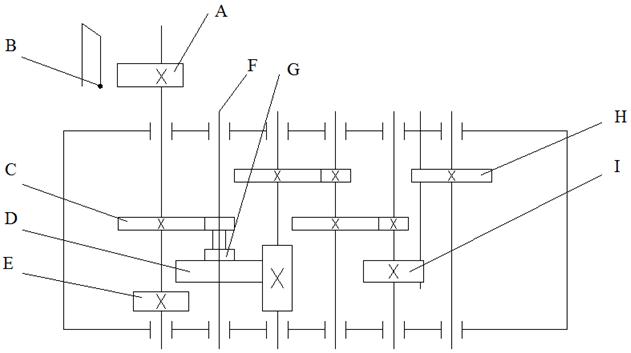

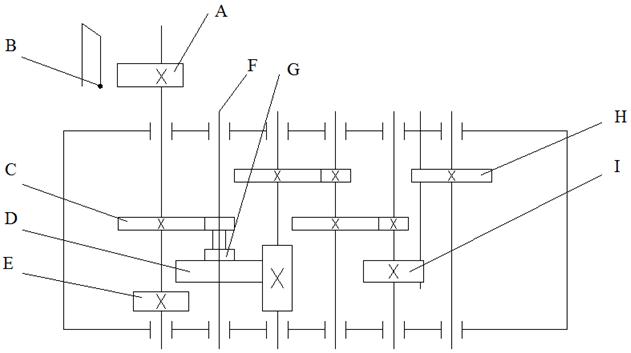

Use the principle of mechanical timer to design. User firstly rotates the spin button to enter a certain force. By the transmission gear, the force is transmitted to the spring. So the spring gradually tightened, and tends to be a trend of relaxation. And because of the gear drive can slow down the relaxation, and the relaxation of the spring can pass through the gear to drive the mixing rod, so the function of the mixing action controlled by mechanical device is realized. The following diagram is a simple schematic diagram of the mechanical timer.

A-switch cam; B-contact; C-friction plate; D-base of pawl; E-winding mechanism; F-principal axis; G-pawl; H-vibrator; I-pawl wheel

Fig. 8. Simple schematic diagram of mechanical timer.

3.4. The Design of Control System of Automatic Tofu Jelly Broken

After the end of curding, the mixture of soybean milk and coagulant required to stand for 20 minutes or so, this action is called tofu jelly squat. In essence, tofu jelly squat is the continuation of coagulating proteins. The time of tofu jelly squat can be controlled by the SCM. Tofu jelly will be broken after tofu jelly squat to seperate water for the first time. Automatic breaken device is to achieve the similar function of artificially tofu jelly broken action. Tofu jelly will be broken into pieces after tofu jelly squat and put into another box with tofu cloth and a lot of small holes to filter a portion of water.

3.5. The Design of Control System of Automatic Squeezing

Squeezing is to press out excess water from the solid-liquid mixture solidified into tofu jelly. Soy milk, tofu jelly and lactone tofu don’t need to be pressed. As show in Figure 4, a water box is arranged on the tofu box to store the 500g-1000g water, and a large plastic bag is put between the bean curd box and the water box. The bottom plate and the side plate of tofu box have small holes to discharge excess moisture in the tofu curd easily. The box is used to store the wastewater.

The working principle is: at first, the mixed liquid of coagulant and water are placed in the box. After grinding and heating the soybean milk, flowing into the box. Wait about 20 minutes for tofu jelly squat, and then open the small valve on the water box. Then the water will flow into a fixed bag, and the next is to repress the tofu jelly.

4. Circuit Design

Fig. 9. The overall circuit diagram.

The lowest water level cannot be lower than the present value, the highest water level cannot be higher than the present value, and the cup lid must be closed to fix the filter to the cup body. If these requirements are not met, it is possible to dry burning, overflow, filter tilt, etc. Tofu machine must first detect these states before work, if it meets the requirements, then enter the normal working procedures, otherwise it will alarm.

When the SCM detects the abnormal state, there comes the alarm; it also need to prompt the user when it starts and ends. Here is the buzzer as alarm to achieve the desired requirements by controlling the number and length of the buzzer sound.

The household tofu machine has five functions, respectively, gypsum tofu, brine tofu, tofu, soy milk, automatic cleaning. The user can select the desired function by pressing the corresponding button. Before the users chose, the five indicators light, when the user presses a button, the corresponding indicator lights, the other indicator is off, and the buzzer short beep sound, SCM will run the program of the button to achieve the selected function.

5. Conclusions

In this article, a new automatic tofu machine was designed, including mechanism system design and control system design. It can be used to produce tofu at home based on traditional techniques. The research and development of the control system of the household tofu machine makes the automatic production of tofu come true for the family’s daily life. Besides the production of soy milk, it also can make soy milk, brine tofu, gypsum tofu, tofu, tofu, and has the automatic cleaning function. In order to make it more convenient for families to use, it also has small volume, product moderation and easy-operation.

In addition, it makes the traditional process of making tofu digital, and also plays a significant role in its preservation and spread.

References

- TSAI, S. J.; LAN, C. Y.; KAO, C. S.; CHEN, S. C. Studies on the yield and quality characteristics of tofu. Journal of Food Science, 1981, 46(6): 1734-1737.

- Du Lianqi, Han Lianjun. Tofu’s New Technology of High Quality Production. BeiJing: Gold Shield publish, 2009: 35-54.

- Dr. K. J. Dąbrowski, Prof. Dr. A. Rutkowski, Dr. sc. K. D. Schwenke. Food / Nahrung, 1986, 30(30): 400-402.

- T. Watanabe. Science of tofu. Kyoto, 1997.

- P. A. Murphy, H. P. Chen, C. C. Hauck, L. A. Wilson. Soybean protein composition and tofu quality. Food Technology, 1997, 86-110.

- Beddows, C. G. and Wong, J. (1987a) Optimization of yield and properties of silken tofu from soybean. International Journal of Food Science & Technology, 1987, 22(1): 15–21.

- Jiang, X. Design and research on soybean-milk machine. Advance Journal of Food Science & Technology, 2015, 7(2).

- Fu, L.. Research on Modeling Design of Industrial Product. Changchun: Jilin People Press, 2002: 129-133.

- Jiang, X.. Design and application on mini type food slicer. Advance Journal of Food Science & Technology, 2013, 5(10).

- Jiang, X.. Method of humanity design for food slicer. Advance Journal of Food Science & Technology, 2014, 6(4).

- Jiang, X.. Development design of new age food machinery. Advance Journal of Food Science & Technology, 2014, 6(1): 140-143.

- Kang, Y., D. Wu, G. Hou. Electrical Appliance Product Design. Beijing: Mechanical Industry Press, 2012: 41-45.

- Miao, C.. Soybean milk machine design research based on lifestyle theory. Product, 2013: 36-37.

- Qi, P., M. Liu, H. Jiang, J. Fan and Z. Wang. The design of the automatic mill. Journal of Agricultural Mechanization Research, 2012: 157-160.

- Qiu, S.. Modeling Design Basis. Beijing: Tsinghua University Press, 2005: 55-64.

- Li Jinfeng. The charm of soy-bean milk. Guangdong: Shantou University Press, 2008: 5.

- H. J Hou, K. C Chang, M. C Shih. Yield and textural properties of soft tofu as affected by coagulation method. Journal of Food Science, 2006, 62(4): 824-827.

- Shih M C, Hou H J, Chang K C. Process Optimization for Soft Tofu. Journal of Food Science, 1997, 62(62):833-837.

- Shen C F, Man L D, Buzzell R I, et al. Yield and Quality of Tofu as Affected by Soybean and Soymilk Characteristics: Glucono-delta-lactone Coagulant. Journal of Food Science, 2006, 56(1): 109-112.

- Gupta. Texture and microstructure of soybean curd (tofu) as affected by different coagulants. Food Microstructure, 1986, 5(1): 83-89.

- Deman, JM; Deman, L; Gupta, S. Texture and microstructure of soybean curd (tofu) as affected by different coagulants, Food Microstructure, 1986, 5(1): 83-89.

- Cai T D, Chang K C. Characteristics of production-scale tofu as affected by soymilk coagulation method: propeller blade size, mixing time and coagulant concentration. Food Research International, 1998, 31(4): 289-295.

- Shurtleff W, Aoyagi A. Tofu and Soymilk Production. The Book of Tofu. Journal of Agriculture & Social Sciences, 1984.

- Cai T D, Chang K C. Dry tofu characteristics affected by soymilk solid content and coagulation time. Journal of Food Quality, 2007, 20(5): 391-402.

- Yang Jian. The original and development of Chinse tofu. The 8th China food culture research seminar, Sichuan: 2003: 217-219.

(Pei Feng)

(Pei Feng)