| 1. | ||

| 2. | ||

| 3. | ||

| 4. | ||

| 5. | ||

| 6. | ||

Experimental Study of the Holes Density Effect on Film Cooling Performance

Muwafaq Sh. Alwan1, Humam K. Jalghaf2, *, Reyadh Ch. Al-Zuhairy3

1Computer Engineering, AL-Iraqia University, Baghdad, Iraq

2Mechanical Engineering, University of Technology, Baghdad, Iraq

3Ministry of Higher Education and Scientific Research, Baghdad, Iraq

Email address

(H. K. Jalghaf)

(H. K. Jalghaf) Citation

Muwafaq Sh. Alwan, Humam K. Jalghaf, Reyadh Ch. Al-Zuhairy. Experimental Study of the Holes Density Effect on Film Cooling Performance. Engineering and Technology. Vol. 3, No. 4, 2016, pp. 67-73.

Abstract

The present work concentrates the experimental investigation of effusion cooling performance for different holes density at different blowing ratio. The film cooling effectiveness and local heat transfer coefficient for difference holes density have been investigated on a flat plate. The investigations were done by using a single test transient IR thermography technique. Two models of staggered holes arrangement are investigated. The holes diameter is 2 mm for model 1 and 2 mm for model 2. The longitudinal distance (X/D) and the span distance between two neighboring holes (S/D) are fixed with 8 and 3 respectively the attitude of the holes is fixed at inclination angle (θ = 30°). The blowing ratios, cold to hot air flow ratio, have been changed three times (BR= 0.5, 1.0, and 1.5) during the experimental program. The experimental investigation shows that the thermal performance increases as the holes density increases for all blowing ratios, and the film cooling effectiveness decreases as the blowing ratio increases for the two models.

Keywords

Effusion Cooling, Blowing Ratio, Effectiveness, Holes Density

1. Introduction

Thermal efficiency and power output of gas turbine increases with increase turbine rotor inlet temperature. Most of the modern gas turbine are now operating with turbine inlet temperature in the range of 1800 K to 2000 K, which near the melting point of the alloys used in the turbine components, And higher (TIT) requires introduction of new materials and / or the usage of efficient means and methods of turbine blades cooling to maintain the blades below thermal failure condition during operation.

Modern blades use film cooling to protect the blades outer surface from hot gases. Film cooling is a technique used extensively in turbo machinery. This techniques inject cool air into the hot side to replace the hot mainstream flow with coolant or at least reduce the local temperature of the flow.

Effusion cooling, which contains an array of closely spaced discrete film cooling holes, is widely used to cool and insulate the component metal from the hot mainstream flow. The cooling effectiveness of an effusion cooling plate depend on several parameters, such as hole spacing, angle, diameter, etc.

Review on turbine cooling technology developments has been well described. Andrews et al. [1] investigated (90 deg.) cooling hole for a number of different arrays and found that there was a significant improvement in the overall cooling effectiveness for a larger hole relative to a smaller hole. Andrews et al. [2] also compared normal (90 deg.) and inclined film holes (30 deg. and 150 deg.) for an array of effusion holes and found that cooling effectiveness improved with inclined holes. The counter flow holes (150 deg.) resulted in reverse flow and good cooling performance at low coolant flows but not at high coolant flows. Assim H. Yousif et al [3], studied the film cooling performance for two rows of staggered holes with opposite orientation angles are presented to determine the heat transfer coefficient and film effectiveness under different holes attitude. Experimental investigations were done on a flat plate by using a single test transient IR thermograph technique. The attitude of the downstream row holes is fixed at inclination angle of (θ=30°) and orientation angle of (Ɣ=0°), while the upstream row holes is fixed with opposite orientation angle (Ɣ=180°) and the inclination angles are changed three times as (θ=20°, 30°, and 40°). Three different blowing ratios (BR) =0.5, 1.0, and 1.5 are used in experimental program at each case. Enhancements were observed, in which as the blowing ratio increased and the inclination angle of upstream row decreased, the film cooling effectiveness and heat transfer coefficient are increased. Gustafsson and Johansson [4] investigated the temperature ratios and velocity ratios between hot gas and coolant, and different injection hole spacing, inclination angle, and thermal conductivity of the test plate. Ekkad et al. [5] obtained both film cooling effectiveness and heat transfer coefficient from a single test by means of the transient infrared thermography technique. The advantage of IR technique was exhibited adequately in these previous research efforts. In terms of the wider temperature range handled than the liquid crystal technique and more detailed 2D temperature field information with better accuracy. It is seen that these research with successful employed of the IR technique enriched higher quality data in the literature, but the effect of the deflection angle of the injection holes was not attempted. Dia and Lin [6] investigated numerically three film cooling configurations, (cylindrical hole, shaped hole, crescent hole). All holes were inclined at 35̊ on a flat plate. All simulations are conducted at blowing ratio of 0.6 and 1.25, length to diameter ratio of 4 and pitch-to-diameter ratio of 3. They use (RANS) equations, the energy equation, and two-layer ![]() turbulence models. For the numerical investigation the commercial CFD software FLUENT with standard

turbulence models. For the numerical investigation the commercial CFD software FLUENT with standard ![]() turbulent models is applied. They found that the crescent hole exhibits the highest film cooling effectiveness among the three configurations both in spanwise and streamwise especially downstream of the interaction of the two holes. Muwafaq. Sh. Al [7] presented experimental and numerical investigations of film cooling performance for two rows of circular holes. The experimental work was carried out using a single test transient IR thermography technique. Three blowing ratios of (BR= 0.5, 1.0, and 1.5) were investigated during the experimental program, The experimental results showed that using upstream oriented jet holes row over conventional single jet holes row did enhance the average cooling performance. For the presented approach, the result showed that for the same inclination and orientation angles, the staggered arrangement gives better cooling performance than the inline arrangement. He stated that the evaluation of cooling performance did detect well by using heat flux ratio technique rather than effectiveness technique whereas the later did not detects the effects of resistance of heat transfer created by film coolant. Martiny et al. [8] used a very low injection angle of (17 deg.) for an effusion, film cooling plate in which they measured adiabatic effectiveness levels for a range of blowing ratios. Their results indicated significantly different flow patterns depending on the cooling jet blowing ratio. It is important to recognize that their study used only four rows of cooling holes and as will be shown in this paper, this small number of rows did not allows for a fully developed condition to occur.

turbulent models is applied. They found that the crescent hole exhibits the highest film cooling effectiveness among the three configurations both in spanwise and streamwise especially downstream of the interaction of the two holes. Muwafaq. Sh. Al [7] presented experimental and numerical investigations of film cooling performance for two rows of circular holes. The experimental work was carried out using a single test transient IR thermography technique. Three blowing ratios of (BR= 0.5, 1.0, and 1.5) were investigated during the experimental program, The experimental results showed that using upstream oriented jet holes row over conventional single jet holes row did enhance the average cooling performance. For the presented approach, the result showed that for the same inclination and orientation angles, the staggered arrangement gives better cooling performance than the inline arrangement. He stated that the evaluation of cooling performance did detect well by using heat flux ratio technique rather than effectiveness technique whereas the later did not detects the effects of resistance of heat transfer created by film coolant. Martiny et al. [8] used a very low injection angle of (17 deg.) for an effusion, film cooling plate in which they measured adiabatic effectiveness levels for a range of blowing ratios. Their results indicated significantly different flow patterns depending on the cooling jet blowing ratio. It is important to recognize that their study used only four rows of cooling holes and as will be shown in this paper, this small number of rows did not allows for a fully developed condition to occur.

At the present work, experimental investigations were done to evaluate the effusion cooling performance for different blowing ratio and different holes density in order to determine the heat transfer coefficient and the film cooling effectiveness on a flat plate by using a single test transient IR thermograph technique.

2. Experimantal Facilities

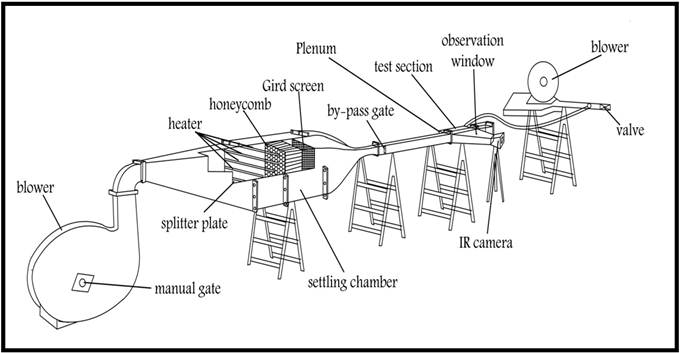

Low speed open duct test rig is used at the present investigation to supply uniform warm air to the test section. A schematic diagram of the test rig is shown in Fig. (1). The mainstream air supply is the ambient air drawn by a blower. The blower is running with 2800 rpm. Manual open gate is used to control the air speed in the test section. The blower exit area having rectangular shape with dimensions of (6.3´13.1) cm. The blower is supplied with bend having the same dimensions of the blower exist and then connected to a diffuser having rectangular cross-section area of inlet and outlet dimensions as (6.3´13.1) cm and (35´50) cm respectively and length of (82) cm. Air flowing through diffuses occupied with splitter plates into a constant area rectangular settling chamber of cross-section area (35´50) cm and length of 70 cm. The settling chamber after modification contains four grid screen and one row of honeycomb located after the electrical heaters. This ensures adequate mixing of hot air and uniform temperature distribution throughout the test section. Then the warm air routed through a convergent-divergent contraction having a rectangular cross-section area from (35´50) cm to (5´10) cm and length of 70 cm. In order to allow the air to reach the desired temperature, the air is initially routed out away from the test section by using by-pass gate passage. The temperature of the air is continuously monitored at the exit of the gate and when the desired temperature is reached, the gate is fully opened manually and air flow passes into a test section through a rectangular duct area. To minimize heat losses to the surrounding, the settling chamber and the test section duct are insulated completely. The test section has 50mm width and 100mm height. The bottom plate of the test section is made of (234x123) mm Plexiglas of 10mm thickness. The operating velocity of the hot air in the test section is controlled to run from 20 to 40m/s through the experimental program.

Figure 1. Schematic of the test rig.

A centrifugal air blower of blowing capacity of (22.17) m3/min was used to supply the coolant air to the plenum. The plenum was located below the test plate. The coolant air enters a plenum then ejected through holes into the test section. The coolant air pressure measured at the inlet of the test section. Digital thermometers were used to measure the mainstream and coolant air temperature. Pre-testing showed that all holes had the same flow rate and temperature conditions.

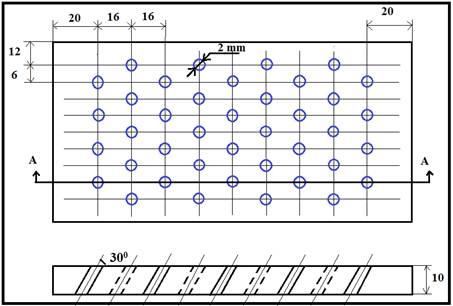

The coolant air injected from the holes is mixed with the hot mainstream in the test section. The test section has 5 cm width, 10 cm height and 23.4 cm length. The bottom wall of the test section work as a test model, three models with different hole pitch ratio are prepared, each model made of (234x100) mm Plexiglas plate of 10mm thickness. The bottom model plate can be removed easily to be replaced by another model at each test. Each model is provided with seven rows of holes, these models are arranged with staggered row holes. The holes diameter is 4mm, the longitudinal distance (X/D) are 8D, 10D and 12D respectively, and the span distance between two neighboring holes (S/D) are 7D as shown in figure (2). The attitude of the holes is fixed at inclination angle (θ = 30°), where the inclination angle (θ) is defined as the angle between the centerline of the hole and the surface of the test wall. Data is taken for only three middle rows of holes to reduce the effects of the side wall.

Figure 2. Details of two test models: X/D= 8, S/D = 3 (a) D=2 mm, (b) D=4 mm.

3. Surface Temperature Measurment

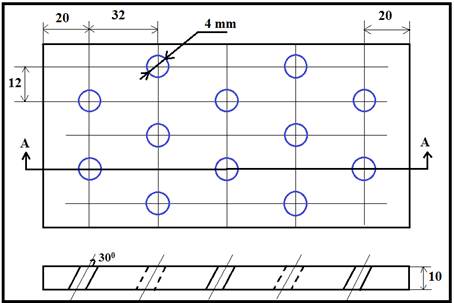

The surface temperature of the test plate is measured using an infrared thermograph technique. The IR system used is a Fluke Ti32. Figure (3) shows a picture of the IR camera. The camera has a range of-20°C to +600°C. The thermal image can be displayed using standard color palettes or Ultra Contrast TM color palettes. Fluke Ti32 utilizes uncooled micro bolometer long wave detectors to sense IR radiation.. The test surface is heated by warm mainstream. The temperatures obtained by both measuring way is recorded during the heating process until achieving a steady state condition. Due to the emissivity of the test surface the temperature recorded by IR camera is differed from the temperature obtained by the thermocouple, and then IR camera is adjusted until both reading temperatures are matched.

The IR images taken for the test surfaces at each test are stored in the SD memory of IR camera. These images are transferred from SD memory to PC memory. Then the middle region of the test surface area is then selected to eliminate the effect of the test section wall with using camera software, Smart View Software Program. IR images, which exhibit the temperatures distribution as colors code, is converted to corresponding temperature digit values by using Smart View Software and then saved as output data in Excel sheet.

Figure 3. Photography of the IR camera.

4. Procedure

Consider the transient flow over a flat plate. In this case, the test plate is initially at a uniform temperature Ti, and the convective boundary condition is suddenly applied on the plate at time t > 0. Now, the heat is assumed to be conducted only in the x-direction and perform an energy balance on the plate. Therefore the one-dimensional transient conduction equation is

![]() (1)

(1)

The main approximation often applied to analyze transient conduction is the semi-infinite approximation. The semi-infinite solid assumptions are valid for the present investigation for two reasons. Firstly, the test duration is small, usually less than 60 seconds. Secondly, the hot air flows over the test surface is made from Plexiglas of, low thermal conductivity, low thermal diffusivity, and low lateral conduction. Therefore, the solution of equation (1), as given by Holman and Bhattacharyya [9], is as follows:

![]() (2)

(2)

Where Tw measured by using IR camera, all the other variables in the equation (2) are either known variables or measured variables except the heat transfer coefficient (h).

In the film cooling case, the film should be treated as a mixture of air mainstream and the coolant air, the mainstream temperature (Tm) in equation (2) has to be replaced by the film temperature (Tf). Therefore, equation (2) becomes as:

![]() (3)

(3)

A non-dimensional temperature term is known as the film cooling effectiveness (η), and is defined as:

![]() (4)

(4)

Equation (3) has two unknowns (h and Tf). To solve this equation, two sets of data points are required to obtain the unknowns like:

![]() (5)

(5)

![]() (6)

(6)

In this case, a transient infrared thermograph technique will be used to obtain both h and η from a single test, as described by Ekkad et al [10]. Thus, two images with surface temperature distributions are captured at two different times during the transient test.

A net heat flux ratio is used to measure the combined effect of film effectiveness and heat transfer coefficient Ekkad and Zapata [11]:

![]() (7)

(7)

The value for the overall cooling effectiveness (ø) ranges between 0.5 and 0.7. A typical value is Ø = 0.6, and this in general assumed in the present experimental analysis.

The IR images for models surface at each investigated test was captured and stored by a thermal camera. These images are transferred to the PC. Smart View Software program supplied with camera can be used to limit the selected area to avoid the effect of the test section walls. The IR images converted to corresponding temperature digital values and then saved as data in Excel sheet. MATLAB Software programs are prepared using a semi-infinite solid assumption to introduce the film cooling effectiveness and heat transfer coefficient contours. Equations, (4), (5), (6), and (7) was solved using MATLAB Software, Smart View Software, and Excel Software.

The uncertainty of measurement was determined by using the methodology described by Holman and Bhattacharyya [12]. Error estimates for each variable are as follows: mainstream temperature ∆Tm = ± 0.2°C, initial temperature ∆Ti = ± 2°C, wall temperature ∆Tw = ± 2°C and coolant temperature ∆Tc = ± 0.2°C. The camera frame rate is 60 Hz resulting in a time error ∆t = ±0.125 sec. and the test surface properties (α and k) uncertainty are taken from tabulated values, as a custom, 3% relative uncertainty is assumed for both variables. The resulting average uncertainty for heat transfer coefficient and film effectiveness is ±8.2% and ±11.0%, respectively.

5. Results and Dicussion

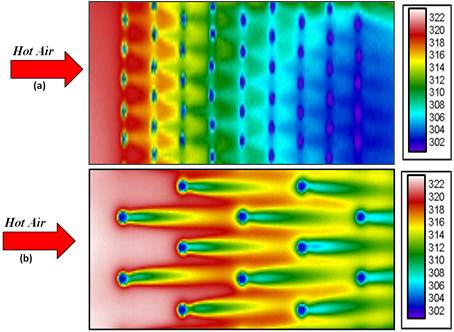

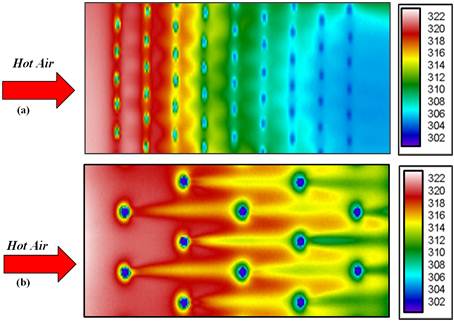

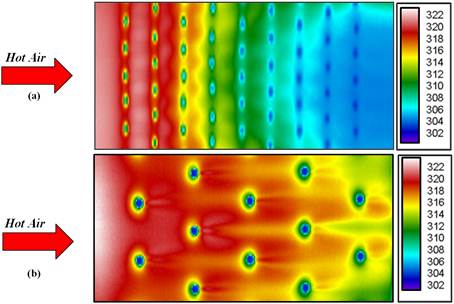

Fig. (4 to 6) show the effect of holes density on the temperature distribution for different blowing ratios (BR= 0.5, 1.0, and 1.5). Comparison between model 1 and model 2 showed that the model 1 gave high protection than the model 2 for the three blowing ratios. Also figures (4 to 6) show that the coolant temperature distribution decreases as the blowing ratio increases for the two models.

For a low blowing ratio (i. e. BR=0.5), the mainstream flow close to the test surface. Also, the jet streamlines seems to go towards the surface and the mainstream flow depart upward, therefore the mainstream push the jet towards the surface. For a high momentum ratio (i. e. BR=1.5), and since the momentum of the jet is relatively high, the jet is separated away into the mainstream. These results have the same trend as in the results obtained by Ref. [12,13].

Figure 4. Contours of temperature distribution for: (a) model 1 and model 2 at BR=0.5.

Figure 5. Contours of temperature distribution for: (a) model 1 and model 2 at BR=1.0.

Figure 6. Contours of temperature distribution for: (a) model 1 and model 2 at BR=1.5.

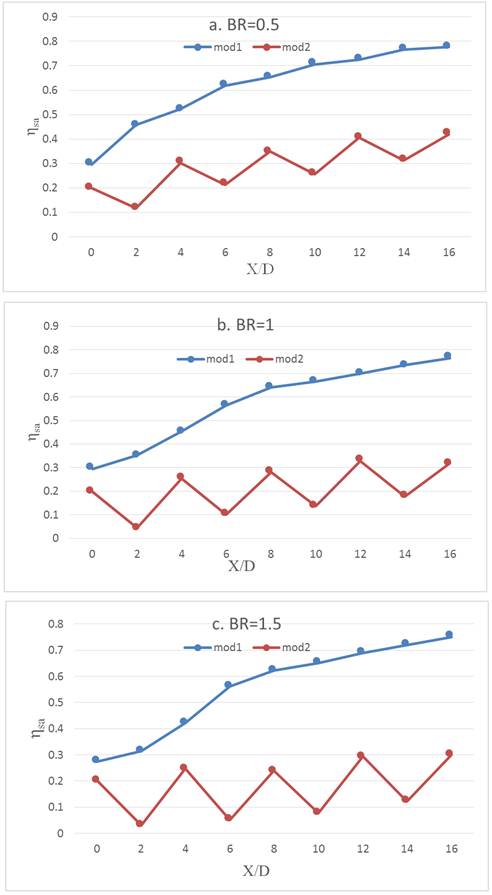

Fig. (7) presents the span wise averaged film effectiveness (ηsa). (ηsa) is calculated as the average values taken from the local reading of 46 pixels in span wise direction in the center of the holes and the mid distance between two holes. Figures (7.a, b and c) show that the model 1 gave high values of (ηsa) as compared to the model 2.

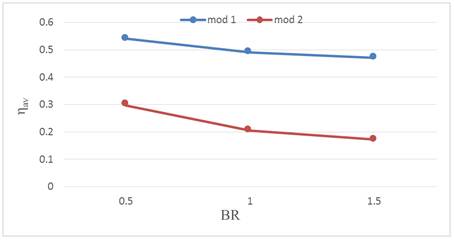

The overall average film cooling effectiveness for the entire selected area Ao (ηav) was calculated from the values of local film cooling effectiveness (η) for the entire pixels values included by the area (Ao). Fig. (8) shows the effect of blowing ratio on (ηav) for the two models. This figure shows clearly that the values of (ηav) for the model 1 are higher than the other model 2. It appears also that the values of (ηav) decreases as the blowing ratio increases for the two models.

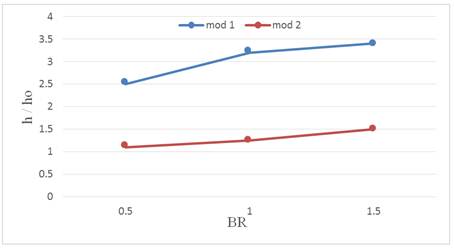

As a matter of fact, the enhancement of the blade surface protection is done by keeping the local heat transfer coefficient (h) as low as possible. The local heat transfer coefficients are calculated from the data of two IR images taken in successive times as described above. The average of the local heat transfer coefficient ratios (h / ho), in which (h and ho) represent the heat transfer coefficient on the plate surface with and without film cooling respectively are presented in Fig. (9). The values of the average heat transfer coefficient ratio for the model 1 are higher than that the model 2 for all blowing ratios and (h/ho) is increased with increasing the blowing ratio. The increment of (h/ho) is due to that the jet injection produces high turbulence level inside the mixing region.

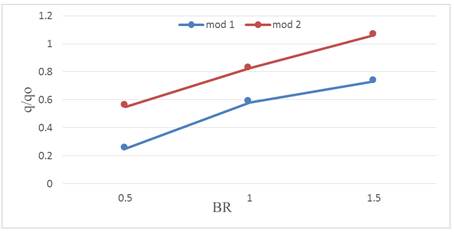

In the practical application, turbine designers are concerned with the reduction of heat load to the film protected surface. The heat load can be presented by combining film cooling effectiveness (η) and the heat transfer coefficient ratio (h/ho), according to equation (7), therefore the ratio (q/qo) can be calculated. (q/qo) represent the reduction in heat flux at the tested surface with the presence of coolant air. If the values of these ratios are less than 1, then the film coolant is beneficial according to Ref. [16], while if the values are greater than 1, therefore effect of the film coolant is poor.

Fig. (10) shows the effect of the blowing ratio on the overall heat flux ratios (q/qo). It is clear that from this Figure the model 1 provides significant reduction of heat flux at all tested BR than that of the model

Figure 7. The span wise averaged film effectiveness (ηsa) with X/D.

Figure 8. Effect of blowing ratio on (ηav).

Figure 9. Effect of blowing ratio on (h / ho).

Figure 10. Effect of blowing ratio on (q/qo).

6. Conclusion

The present work has reached to the following conclusions:

A The thermal performance increases as the holes density increases for all blowing ratios.

B The film cooling effectiveness decreases as the blowing ratio increases for the two models.

C The values of the average heat transfer coefficient ratio (h/ho) for the model 1 are higher than that the model 2 for all blowing ratios and (h/ho) is increased with increasing the blowing ratio.

D The model 1 provides significant reduction of heat flux at all tested BR than that of the model 2.

Nomenclatures

| D | hole diameter | m |

| h | Heat transfer coefficient with film cooling | W/m2 •K |

| ho | Heat transfer coefficient without film cooling | W/m2 •K |

| k | Thermal conductivity | W/m2 •K |

| S | Span wise hole spacing | m |

| t | time | s |

| T | Temperature | °C |

| Tc | Coolant temperature | °C |

| Ti | Initial temperature | °C |

| Tm | Hot mainstream temperature | °C |

| Tw | Wall temperature | °C |

| Uc | Coolant velocity | m/s |

| Um | Hot mainstream velocity | m/s |

| η | Film cooling effectiveness | - |

| ηav | Average film cooling effectiveness | - |

| ηsa | Stream wise Average film cooling effectiveness | - |

| ρ | Density of air | kg/m3 |

| ρc | Density of coolant air | kg/m3 |

| ρm | Density of hot mainstream | kg/m3 |

| θ | Inclination angle | Degree |

References