Determination of Physicochemical Properties of Cassava Mosaic Disease (Cmd) Resistant Varieties and Their Potentials for the Manufacture of Noodles

Ugo Chijioke1, Philippa Chinyere Ojimelukwe1, *, Doris Akachukwu2

1Department of Food Science and Technology, Michael Okpara University of Technology, Umudike, Abia State, Nigeria

2Department of Biochemistry, Michael Okpara University of Technology, Umudike, Abia State, Nigeria

Email address

(P. C. Ojimelukwe)

Citation

Ugo Chijioke, Philippa Chinyere Ojimelukwe, Doris Akachukwu. Determination of Physicochemical Properties of Cassava Mosaic Disease (Cmd) Resistant Varieties and Their Potentials for the Manufacture of Noodles. International Journal of Biological Sciences and Applications. Vol. 3, No. 1, 2016, pp. 22-28.

Abstract

The physicochemical properties of twenty Cassava Mosaic Disease resistant varieties and their potentials for the manufacture of noodles were investigated. The cassava varieties were processed into High Quality Cassava (HQCF) and two varieties with good noodle qualities were selected and fortified with soybean. The moisture, starch, sugar, amylose and amylopectin content differed slightly for different varieties. The peak viscosity was in the range of 165.25-453.33 for all the varieties. The trough period was in the range of 32-156 for the varieties. Variety 4(2) 1425 had the highest solubility while 95/0166 was least soluble. TME419 had the highest swelling power while 96/109A had the least. TME419 had the highest dispersibility of 75.10% while 99/6012 had the least (60.95%). Water absorption capacity was highest in 92B/00068 and least in TME419. Varieties M98/0068 and 94/0026 showed the best qualities for noodle preparation. There was no significant (p > 0.05) difference between the moisture content of the fortified noodles from the two varieties and their control (indomie). However, the protein, ash, fat, pH, and colour of the noodles differed significantly (p < 0.05) from the control. Sensory evaluation of the fortified noodles from the two varieties showed they were acceptable. However, they differed significantly in terms of taste, colour, texture and general acceptability. The physico-chemical properties of the high quality flours from the cassava mosaic disease resistant varieties has revealed that they can be very useful as food and also industrially for the production of noodles. Potentials of twenty Cassava Mosaic Disease resistant varieties for the manufacture of noodles were investigated in this research. The cassava varieties were processed into High Quality Cassava Flour (HQCF) and the physicochemical and rheological properties of the flours were determined. From the basic data, two cassava varieties were identified and used to formulate noodles. The quality characteristics of formulated noodles were compared with that of a commercial sample (Indomie noodles). The moisture, starch, sugar, amylose and amylopectin content of the cassava flours differed slightly for different varieties. The peak viscosity was in the range of 165.25-453.33 for all the varieties. The trough period was in the range of 32-156 for the varieties. Variety 4(2) 1425 had the highest solubility while 95/0166 was least soluble. TME419 had the highest swelling power while 96/109A had the least. TME419 had the highest dispersibility of 75.10% while 99/6012 had the least (60.95%). Water absorption capacity was highest in 92B/00068 and least in TME419. Varieties M98/0068 and 94/0026 showed the best qualities for noodle preparation. The protein, ash, fat, pH, and colour of the noodles differed significantly (p < 0.05) from the control. Sensory evaluation of the fortified noodles from the two varieties showed they were acceptable. However, they differed significantly (p < 0.05) from the unfortified noodles in terms of taste, colour, texture and general acceptability.

Keywords

Physico-Chemical, Cassava Mosaic Disease, High Quality Cassava Flour, Noodle, Fortified

1. Introduction

Cassava is one of the widely cultivated crop that serves as staple food for more than 800 million people in Africa [1]. Nigeria is the highest producer of cassava with about 54 million tonnes per annum [2]. Despite this, Nigeria is not yet among the major exporters of cassava in the international market primarily due to subsistence production methods and limited value addition chains. Of the 248 million tonnes of cassava produced worldwide in 2012, 58% was produced in Africa [3]. As a result of the increasing uses of cassava and its products, a lot of initiatives have been put in place to ensure its production in commercial quantities.

Cassava (Manihot esculenta Crantz) belongs to the family of Euphorbiaceae [4]. It is a tropical plant with woody shrubs and has been reported to originate from North east Brazil and Central America [5]. It is a carbohydrate rich food [6]. Cassava serves mainly as food in the form of garri, fufu/akpu, lafun and so on in Nigeria. High Quality Cassava Flour (HQCF) another product from cassava is used widely in bakery for the production of diverse confectionaries and biscuits. Starch produced from cassava is also used by pharmaceuticals as adhesives and seasonings. Cassava master plan [7], reported that Nigeria is still importing products like starch, flour and sweeteners which can be made from cassava. This is largely due to limited research on value addition methods for development of cassava products for industrial use.

A number of policies have been put in place by Nigerian government to ensure increase production and utilization of cassava and its products. The IITA from 2003-2010 has also worked hard to develop improved varieties of cassava that are resistant to cassava mosaic disease (CMD). This research therefore aimed to evaluate the physico-chemical properties of flours from these CMD resistant varieties and their potentials for industrial use in the manufacture of noodles.

2. Experimental

2.1. Materials

Twenty cassava mosaic disease (CMD) resistant varieties were harvested from the Onne IITA sub-station cassava farm plot, Rivers state, Nigeria and processed into high-quality starch (HQCF).

2.2. Preparation of Flour Samples

The cassava varieties were weighed, pealed and washed. The pealed roots were chipped using a 274kW diesel engine powered chipping machine (IITA OE 1029 Model). The chipped samples were oven dried (Galenkamp Plus Oven Model) at 60°C for 24h. The samples were finally milled and sieved using C1 Lotec Mill (unit 1093). The products were properly labelled and sealed using an impulse sealing machine (Mode No. ME-300H) set at 5°C. Flour samples from the different varieties were used for physicochemical analysis. Two varieties having good noodle qualities were selected. The cassava noodles were fortified for noodle preparation using soybean (boiled and dehulled), salt, and egg.

2.3. Determination of Moisture Content

The moisture content of the cassava flour was determined by the gravimetric method by AOAC [8]. Two (2) grams of the flour was weighed into a clean dried pre-weighed moisture can. It was allowed to dry in the oven for 6h at 100°C until a constant weight was obtained.

The moisture was calculated as follows:

% Moisture = (W3-W2) /W1 x 100 (1)

Where

W1=weight of sample used

W2=weight of can + sample before drying

W3=weight of can + sample after drying

2.4. Determination of Carbohydrate

2.4.1. Starch and Sugar Content Determination

The calorimetric method of determination of sugars and related substances was employed. One millimetre (1 ml) of 95% ethanol, 2 ml of distilled water and 10 ml of hot ethanol was added to 0.02g sample, vortexed and centrifuged for 10 min at 2000rpm. The supernatant was decanted and 9 ml of distilled water was added. Quantities of (0.8 ml) distilled water, 0.5 ml phenol and 25 ml H2SO4 were added to the extract. Absorbance was read at 420 nm for sugar determination. While For the determination of starch, HCLO4 was added to sediment for hydrolysis. The sample was allowed to stand for one hour, and vortexed. An aliquot of 0.95 ml of distilled water, 0.5 ml phenol and 2.5 ml H2SO4 were added to 0.05 ml of extract and absorbance of sample read at 420 nm.

Calculation: The sugar and starch contents were calculated on percentage curve = 0.0055 basis.

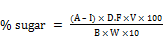

(2)

(2)

(3)

(3)

Where:

A = Absorbance of sample

I = Intercept of standard curve

D. F = Dilution factor based on aliquot taken for assay, 5 ml = sugar, 20 ml = starch.

V = Total extract vol.; 20 ml = sugar, 25 ml = starch.

B = Slope of the standard curve = 0.0055

W = Weight of sample.

2.4.2. Determination of Amylose and Amylopectin

The rapid calorimetric procedure for estimating the amylose content of starch and flour according to the method described by Juliano [9] and Hoover and Ratnayake [10] was employed. A quantity of 0.1g (100 mg) of the samples (flours and starches) was weighed into a 100 ml volumetric flask and 1 ml of 99.7 to 100% (v/v) ethanol and 9 ml of 1 N-sodium hydroxide (NaOH) was carefully added and the mouth of the flask was covered with paraffin or foil and the content was mixed well. The samples were heated for 10 min in a boiling water bath to gelatinize the starch (the timing was started when boiling began). The samples were then removed from the water bath and allowed to cool very well. It was then filled up to the mark with distilled water and shaken well. About 5 ml of the mixture was then pipetted into another 100 ml volumetric flask. Acetic acid (1 N, 1.0 ml) and 2 ml of iodine solution were added, and top to mark with distilled water. Absorbance (A) was then read using spectrophotometer at 620 nm wavelength. The blank contained 1 ml of ethanol, 9 ml of sodium hydroxide, and then boiled and top up to the mark with distilled water. 5 ml was then pipetted into a 100 ml volumetric flask. Approximately, 1 ml of 1 N acetic acid and 2 ml of iodine solution were added and then filled up to the mark, this was used to standardize the spectrophotometer at 620 nm.

The amylase content was calculated as:

% amylose = absorbance x 3.06 x 20 (4)

% amylopectin = 100 - % amylose (5)

2.5. Determination of Rheological Properties

The rheological properties of cassava flours processed from CMD resistant varieties were determined using a Rapid Visco Analyser (RVA Newport scientific super 3D+, Australia). Parameters analysed were peak time, trough, breakdown, final viscosity, set back, and pasting temperature. A quantity of (3g) of each flour sample (on 100% dry matter basis) was weighed into a canister. Twenty-five millimetres (25 ml) of distilled water was added and stirred. The paddle was placed into canister and the canister inserted into the instrument. The measurement cycle was initiated by depressing the motor tower of the instrument when the computer indicated "press down the tower. The experiment runs with the PC attached, takes the reading and draws the graph. The cycle terminates at the end of at least 12 min.

Calculation of dried sample weight:

Since at 100% dry matter (DM) required of sample weight is 3.0g

RVA weight = 100 x 3g (6)

Volume of water = 25.0 ml – Y.

2.6. Functional Properties of Flour

2.6.1. Determination of Swelling Power and Solubility

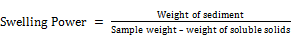

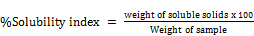

One gram (1.0g) of sample was weighed into 100 ml conical flask. Fifteen (15) ml distilled water was added and stirred for 15 min on a shaker (Gallenkamp flask shaker) at low speed. The mixture was transferred into a water bath (Precision Sc. Co model 83) for 40 min at 80-85°C with constant stirring. A quantity of (7.5) ml distilled water was added to the sample and transferred into a pre-weighed centrifuge tube for 20 min. The supernatant was decanted into a pre-weighed can and dried to constant weight and weighed, for the determination of solubility. The sediment in the centrifuge tube was also weighed for the determination of swelling power. The swelling power and solubility were given as follows:

(7)

(7)

(8)

(8)

2.6.2. Determination of Dispersibility

A quantity of ten gram (10g) of sample was weighed into 100 ml measuring cylinder and distilled water to reach water added to reach volume of 100 ml. The set up was stirred vigorously and allowed to settle for 3 h. The volume of settled particles was recorded and subtracted from 100. The difference was reported as % dispersibility.

% Dispersibility = 100/reading (9)

2.6.3. Determination of Water Absorption Capacity

Fifteen (15) ml distilled water was added to 1g of sample in a pre-weighed centrifuge tube. The tube and mixture was agitated on stural Sc. (U.K Merlin 503) centrifuge. The clear supernatant was discarded and the centrifuge was weighed with the sediment. The amount of water bound by flour was determined by difference and expressed as weight of water bound by 100g dry flour.

WAC = (Sediment – sample weight) x 100 (10)

2.7. Formulation and Preparatory of Noodles from Soybean and Cassava Flour

Varieties having good noodle quality were selected. The varieties, 94/0026 and M98/0068 were chosen based on the following criteria: high amylose content, high breakdown value, low swelling power, and low setback values. The cassava noodles were fortified for noodle preparation using soybean (boiled and dehulled), salt, and egg. Noodles (Indomie brand) were used as control samples. Experimental samples contained the following ingredients: 180g cassava flour, 20g soybean flour, 100 ml water, 1 teaspoon of salt, 1 egg, 45g cassava flour (for pregelling). All dry ingredients (135 gram of cassava flour, 20g soybean and salt) were mixed and passed through a 20 µm (mesh size) sieve for uniform mixing. A quarter of the flour was pre-gelled with hot water and hand-kneaded into the dry ingredients to form the noodle dough, the egg was finally added to the mixture to improve binding quality of the dough. The dough was rested for 15 min, remixed and pressed into a hand-operated extruder. The extruded noodles were boiled for 4 mins, decanted and oven dried at 450C for 12h. Similar processing method was used to produce noodles from five cassava varieties that were not fortified with soybean flour. Samples were allowed to cool, packaged and properly labelled for further analysis.

2.8. Proximate Analysis of Noodles

According to the method described by AOAC (1990) moisture, fat, ash, crude, protein contents of processed noodles and control samples were determined.

2.9. Sensory Evaluation

A 50-member, untrained panel consisting of staff of IITA Onne substation evaluated samples of the cooked noodles. Panelists used a 9-point hedonic scale to evaluate colour, taste, texture and overall acceptability. Evaluation was conducted over a period of 3 days, with three sessions per day: mid-morning and mid-afternoon. Panellists evaluated five samples/session using a conventional 1-9 hedonic scale from (1) dislike extremely to like extremely (9).

2.10. Statistical Analysis

Data were subjected to analysis of variance (ANOVA) and principal component (PCA) using SAS version 8e software (SAS Institute Inc., Cary, NC, USA) at P<0.05. Means were separated using standard error. Values are written as mean ± standard error (SE) of duplicate determinations.

(P. C. Ojimelukwe)

(P. C. Ojimelukwe)