Modification of Different Light Stabilizers for Radiation Resistance of PP

Wangtong He, Xuejia Ding, Ruilong Cai, Han Zhang

Beijing Laboratory of Biomedical Materials, Beijing University of Chemical Technology, Beijing, China

Email address

(Xuejia Ding)

Citation

Wangtong He, Xuejia Ding, Ruilong Cai, Han Zhang. Modification of Different Light Stabilizers for Radiation Resistance of PP. AASCIT Journal of Materials. Vol. 2, No. 3, 2016, pp. 12-19.

Abstract

Radiation can make polymer materials change color and affect many polymer materials radiation processing of the application, so an exploratory examination of the irradiation resistance of polymer materials has a certain significance. This paper through the blending of three light stabilizer 770, 622, 944, with PP, the yellow index, mechanical properties, scanning electron microscopy, thermal performance are analyzed, It can draw a conclusion that light stabilizer 770 has an good irradiation resistant color for PP, in particular when the phr is 0.5, the yellowness index is better than others; light stabilizer though changed the performance of mechanics of materials, but the material is still in the range of application before and after irradiation; light stabilizer makes the material crystallinity increase; epitaxy initial decomposition temperature have different degree of change.

Keywords

Polypropylene, Light Stabilizers, Irradiation, Yellowness Index, Degree of Crystallization

1. Introduction

Isotactic polypropylene (PP) is being extensively used for the manufacture of medical supplies. [1] It is one of the fastest growing synthetic resin productions. Although high energy radiation proved to be an efficient method for the sterilization of materials, PP degrades when exposed to sterilization doses (25kGy) of radiation. [2] The surface of polypropylene color becomes yellow or brown. The deterioration occurs in the polymer during irradiation as well as during post-irradiation storage. [3] The purpose of this work mainly chooses three kinds of light stabilizer were studied, respectively is light stabilizer 770, light stabilizer 622 and light stabilizer 944. It also investigated the irradiation yellow index, mechanical properties, scanning electron microscopy (sem) and thermal analysis of PP. By using three kinds of light stabilizer and PP blending modification, PP macromolecular material developed resistance to radiation, for the future lay a good foundation of medical radiation sterilization.

2. Experimental

2.1. Sample Preparation

PP, the type is T30S, which produced by North Huajin Chemical Industries Group Corporation. The isotactic index greater than 95%, Melt mass flow rate is 3.2 g/10 min. Tinuvin770, Tinuvin622 and Tinuvin944 are from Ciba Specialty Chemicals. We will blend PP with three light stabilizers respectively, then extrusion and injection molding. The maximum temperature of extrusion is 205°C and the highest temperature of injection is 215°C.

2.2. Irradiation

Samples of the injection molding under the electron beam irradiation, the scanning current is 3.25 A, frequency is 300Hz, irradiation dose rate is 10kGy/h, we need 15kGy, 20kGy, 25kGy, 30kGy.

2.3. Yellowness Index Test

The instrument used is rite desktop color i7 spectrophotometer colorimeter colorimeter which is from Rite distributor Ltd. Each sample measured three times, average as a result of the measurement.

2.4. Mechanics Performance Testing

Mechanics performance test using the universal material testing machine, swing arm type impact strength tester, the tensile strength of the measured accord with GB/T 1040-1040 and bending strength live up to the GB/T 9341-2008; impact sample size is 80 mm×10mm×4mm.

2.5. Thermal Gravimetric (TG) Testing

Using the TA company produces the thermo-gravimetric analyzer for the thermal stability of performance measurement, temperature range is at room temperature to 500°C, heating rate of 10°C per minute, we measure the thermal stability of PP incuding before irradiation, after irradiation and pure PP.

2.6. Differential Scanning Calorimetry (DSC) Test

Use Q20 type differential calorimeter scanner test, sample in N2 atmosphere, it starts with heating rate of 50°C/min from 25°C to 250°C, and then from 250°C to 25°C, cool rate is 50°C, the purpose of this is eliminate thermal history of sample, at last, from 25°C to 250°C, at rate of 25°C/min; we also need record the DSC curve in different stages.

2.7. Scanning Electron Microscopy (SEM) Test

We will impact test section after spray gold to observe the morphology of cross section in the scanning electron microscopy (sem) and to determine fracture form; To brittle fracture surface after chromic acid lotion soaked after 24 min and hot water washing, after spraying gold surface under scanning electron microscope observation of the dispersed phase dispersed; The residual carbon surface after grinding alcohol dissolve the vacuum plating, combustion of carbon residue morphology observed by a scanning electron microscope.

3. Results and Discussion

3.1. Yellowness Index Test Result Analysis

Figure 1. Effect of yellowness of PP under different irradiation dose and only add Photo-stabilizer 622.

From Figure 1 it can see that yellowness index of each formulation high than the pure PP yellowness index. When add attachments to 0.5 622, the yellow index of polypropylene is the largest, irradiation, the sample badly discolored look from the intuitive. Light stabilizer 622 is a convergent hindered amine light stabilizer, has many characteristics, such as molecular weight, resistant to migration of volatile. When the sample and add attachments to 1, 1.5, 2, the yellow index of samples is nearly; In general, light stabilizer 622 PP irradiation effect is not obvious. In the experimental process, we will no longer consider light stabilizer 622 as irradiation resistant additives for polypropylene.

Figure 2. Effect of yellowness of PP under different irradiation dose and only add Photo-stabilizer 770.

Light stabilizer 770 is a low molecular weight hindered amine light stabilizer, it is a kind of powder filler. the yellowness index of any PP mixed with light stabilizer 770 is better than that of pure PP, after irradiation, basically, each kind of formula after irradiation the yellowness index are controlled within 1, possibily, compared with other two kinds of light stabilizer, 770 is a white powder of nanometer level, can be better dispersed in the matrix resin while light stabilizer 944 and 622 are granuliform.

Figure 3. Effect of yellowness of PP under different irradiation dose and only add Photo-stabilizer 944.

It can be see from the above figure same as 622, the yellowness index of any formula include light stabilizer 944 is no better than that of pure PP; the same irradiation dose, with the increase of adding volume fraction, the yellowness index increased, when 944 to the end of two yellowness index is the largest. This may be a light stabilizer 944 molecular weight is big, after irradiation, oxidation and decomposition reaction in itself.

So, as we all know, hinder amine light stabilizers (HALSs) are commonly added to various polymeric materials in outdoor uses as exceent radical scavengers in the order of 0.1% or ess for the prevention of their photodegradation. [4] compare with three light stabilizers, light stabilizer 770 has better resistance to yellowing irradaition effect on PP, therefor, in considering and antioxidants compound with or in the subsequent product production process priority light stabilizer 770 experiment; Light stabilizer 622 belongs to the typical hindered amine light stabilizer. [5] But 622 have a bad effect on the irradiation resistant of PP.

3.2. Mechanics Performance Testing Results

Figure 4. Effect of tensile strength of PP under different irradiation dose and only add light stabilizer 622.

Figure 5. Effect of impact strength of PP under different irradiation dose and only add light stabilizer 622.

It was also told from figure 4 and 5 that with the increase of irradiation dose, light stabilizer 622-ABS material tensile strength decrease, the impact strength increase;Under the condition of the same irradiation dose, as the light stabilizer 622, with the increase of adding amount of material tensile strength decreased, the impact strength has no obvious change. This may be due to ABS and light stabilizer 622 after blending, rigid material increased, the tensile strength decreased, after irradiation, light stabilizer, and the combination of the ABS molecular increased, the impact strength to rise.

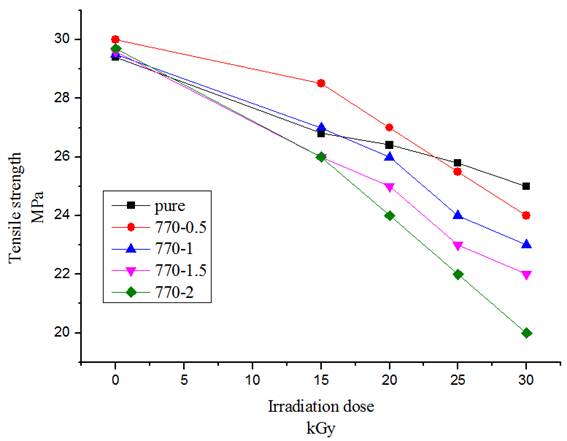

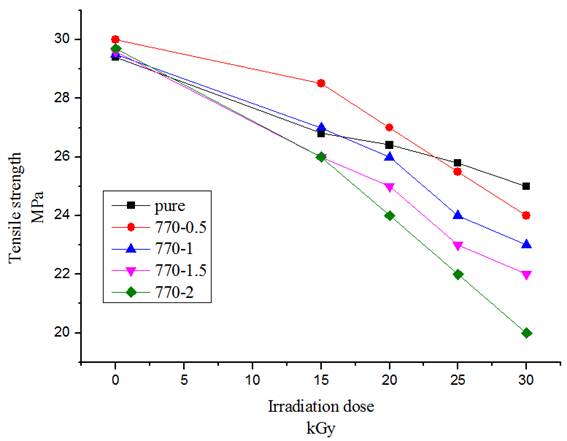

Figure 6. Effect of tensile strength of PP under different irradiation dose and only add light stabilizer 770.

Figure 7. Effect of impact strength of PP under different irradiation dose and only add light stabilizer 770.

It can be seen from here that with the increase of irradiation dose, add light stabilizer 770 ABS material tensile strength decreased, the impact strength increased; When the radiation dose is 0, tensile strength and impact strength changed little; When 30 kGy irradiation dose for material tensile strength is better than that of pure samples, by adding the light stabilizer, the more material tensile strength decreased, while the impact strength not much obvious change.

Figure 8. Effect of tensile strength of PP under different irradiation dose and only add light stabilizer 944.

Figure 9. Effect of impact strength of PP under different irradiation dose and only add light stabilizer 944.

Adding a light stabilizer 944 ABS material is the same as adding stabilizer 770 and 622; the overall trend of material tensile strength and impact strength is identical; The tensile strength decreased with the increase of irradiation dose, impact strength increased. Materials in the process of irradiation it can be occurred the reaction of irradiation crosslinking and the oxidative degradation at the same time; the structure of the materials from linear structure to the shape structure by irradiation crosslink, it enhances the overall mechanical properties; while oxidation degradation can ruin the molecular structure of the material neat and unable to form a stable structure. The addition of light stabilizer will have certain inhibition irradiation crosslinking which makes the mechanical properties better lower. However, light stabilizer has itself will be involved in the process of crosslinking and degradation, it can form stable compound by capturing the radicals.

Figure 10. SEM photographs of polypropylene.

Polymer materials in the process of forming, storage and use, and oxygen molecule chain automatic reaction will happen, the automatic is referred to as the oxidation reaction, also known as aging. [6] in general, the addition of various light stabilizers has not been great influence on the material's mechanical performance, the tensile strength, light stabilizer will reduce the tensile strength of PP material, can improve the impact strength of the material. Light stabilizer 770 formula will not have serious impact on the mechanical properties of the PP, it still can achieve the required strength.

3.3. Scanning Electron Microscopy (SEM) Analysis

Indicates the SEM photographs of pure polypropylene; (b) denotes the SEM photographs of PP added light stabilizer 622 before and after irradiation; (c) expresses the SEM photographs of PP added light stabilizer 770 before and after irradiation; (d) signifies the SEM photographs of PP added light stabilizer 944 before and after irradiation. The section of pure PP is more neat, which belongs to the ductile fracture; After joining light stabilizer 622, impact of silver crack intensity of the surface increases, so does it in the numbers; This is by the addition of light stabilizers in PP crystallization process play a role of heterogeneous nucleation, prompted ascension, the crystallinity of materials, molecular structure more neat, impact is ductile fracture. After irradiation, the material of further increase, increase of crack depth, this is due to the electron beam irradiation on the material inside play a crosslinking effect, increase the toughness. joining light stabilizer 770, PP impact cross section surface obviously becomes more rough and uneven, it shows the morphology features of ductile fracture; Adding the light stabilizer is the same situation in 944 and in 622, the sample fracture morphology for the ductile fracture. Added three kinds of light stabilizer, after irradiation, the sample fracture zone, shows that after irradiation, the action of light stabilizer forces between molecules increase, takes more energy to thrust in the process of impact, so the impact strength increased.

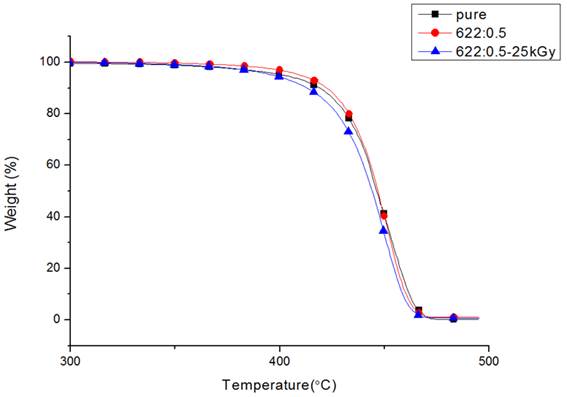

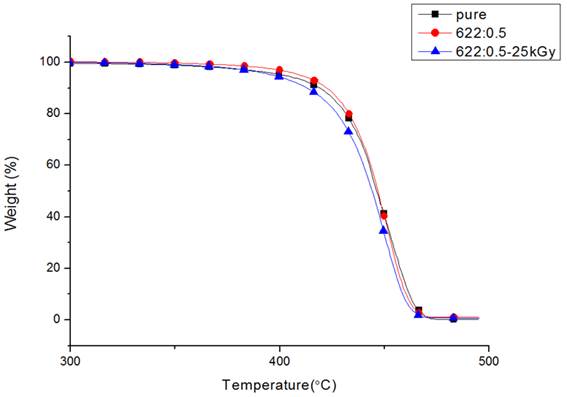

Figure 11. Effect of light stabilizer 622 in PP TGA performance before and after irradiation.

Figure 12. Effect of light stabilizer 770 in PP TGA performance before and after irradiation.

Figure 13. Effect of light stabilizer 944 in PP TGA performance before and after irradiation.

3.4. Thermal Gravimetric Analyzer (TGA) Analysis Results

Thermo-gravimetric curve shows that adding light stabilizer 622, extension of the starting material temperature is 431.71°C, fell to 427.55°C after irradiation. After adding light stabilizer 622, improve the thermal stability of materials but after irradiation, light stabilizer and PP molecular chain structure by a certain degree of damage, it causes thermal stability decreased slightly. In comparison, the initial extension temperature of the light stabilizer 770 is as much as before irradiation the light stabilizer 622, that is 431.8°C. This is because they all have the same structure of hindered amine stabilizer, the thermal stability performance is relatively similar. And after irradiation, the extension starting temperature dropped to 406.43°C, This is because in the process of irradiation, light stabilizer 770 with low molecular weight, such as no other high molecular weight of the stabilizer, antioxidant, formation of high molecular weight, stable structure, Although looked from the yellowing index, light stabilizer 770 have good radiation effect, but its low molecular weight, also to a certain extent, led to the lack of it in thermal stability. Thermal analysis of adding the light stabilizer 944 is the same as the other two similar light stabilizers, The test results are due to radiation energy.

3.5. Differential Scanning Calorimeter (DSC) Results

Figure 14. Effect of light stabilizer 622 in PP crystallization before and after irradiation.

Figure 15. Effect of light stabilizer 770 in PP crystallization before and after irradiation.

Figure 16. Effect of light stabilizer 944 in PP crystallization before and after irradiation.

Table 1. Different additives, crystallization temperature, the crystallinity before and after irradiation.

| | Crystallinity | Crystallization temperature |

| Pure PP | 25.11% | 149.15°C |

| Add light stabilizer 622 | 28.17% | 150.02°C |

| Add light stabilizer 622 after irradiation | 27.44% | 149.37°C |

| Add light stabilizer 770 | 28.18% | 149.92°C |

| Add light stabilizer 770 after irradiation | 29.22% | 149.23°C |

| Add light stabilizer 944 | 29.8% | 149.85°C |

| Add light stabilizer 944 after irradiation | 26.94% | 149.90°C |

It select the amount of light stabilizer for 0.5 PP compared with pure PP and required medical supplies irradiation dose of 25 kgy irradiation, The change of crystallinity analysis before and after the irradiation materials and how does the light stabilizer have effect on the crystallization process. Light stabilizer 622 after adding, crystallization temperature of the material up to 150.02°C, the crystallization temperature lowered to 149.37°C after irradiation. After mixing light stabilizer 622 crystallinity up to 28.17%, compared with pure PP-25.11% crystallinity increased, crystallinity after irradiation before irradiation is slightly lower, at 27.44%, but still higher than that of pure PP before irradiation. This is due to the light stabilizer 622 to put in the process of PP to heat up, form a new nucleation center, which makes improve the crystallinity of PP. Light stabilizer 622 may be due to the influence of irradiation, part of the molecular structure was damaged, to the extent of the heterogeneous nucleation is as obvious as it before irradiation after irradaition. To add the light stabilizer 770 before and after irradiation, the crystallization temperature basic did not change, after irradiation crystallinity rise to 29.22%, this suggests that the addition of light stabilizer 770 formed in PP new heterogeneous nucleation center, improve the crystallinity of materials, after irradiation, the hindered amine light stabilizer structure capture material of free radicals and oxygen free radicals, the formation of new stable products, promote the heterogeneous nucleation of material, the crystallinity a more before irradiation. Adding the crystallinity of light stabilizer 944 is 29.8%, crystallinity decreased to 26.94% after irradiation, This may be a light stabilizer 944 itself is convergent light stabilizer, in PP material internal heterogeneous nucleation effect is more noticeable. After irradiation, light stabilizer 944 on the macro have good resistance to yellowing cause color effect, in the DSC spectra show the crystallinity decreased, may the light stabilizer 944 itself in the process of irradiation influenced by irradiation, molecular structure by a certain degree of damage, affect the ability to resist radiation, it also influence the effect as the center of the nucleation, the crystallinity and the corresponding drop before irradiation. Plastic in the processing and use process, due to light, heat, oxygen and other combination of internal and external factors, and cause the degradation or crosslinking, make its performance becomes bad, yellow appearance, so that the loss of use value. [7, 8] PP irradiated by light oxidation reaction belongs to free radical chain reaction. To slow the light aging effect of resin, it needs to add light stabilizer to block out the chain reaction continues [9] so add the light stabilizer is necessary.

4. Conclusion

This paper focuses on the PP material after adding hindered amine light stabilizer, test characterization of various performance indicators. (1) Light stabilizer 770 has a good ability to improve effect of irradiation color of PP, when join the number 0.5, the yellowing index is minimal, it almost no discoloration. (2) PP after adding light stabilizer, the tensile strength failed, impact strength goes up, along with the increase of irradiation dose, reduced the tensile strength, impact strength increased, adding the light stabilizer 770 formula can satisfy the requirement of the materials required for mechanical properties. Yoshihiko Taguchia [10] had discussed that HALS and its reaction products in PP material are examined distinctively without the use of troublesome pretreatment. (3) Adding the light stabilizer before and after irradiation, the crystallinity of materials were improved, it is formed by light stabilizers in the materials caused by heterogeneous nucleation center. (4) After adding light stabilizer, PP extension of initial decomposition temperature is increased, but after irradiation, light stabilizer 770 due to its characteristics of low molecular weight, epitaxial initial decomposition temperature has a certain degree of decline.

Acknowledgments

The authors thank the National Science and Technology Support Program (2012BAI22B07) for financial support and Beijing chaoyang district coordination innovation project (XC1418)

References

- A. M. Hassan Rezk, M. M. Senna. Gamma-radiation stabilization of polypropylene [J]. Polymer International 28 (1992) 265-270.

- Geymer. D. O. The radiatin chemistry of macromolecules. Vol. Ⅱ . ed. M. Dole. Academic Press. New York. 1973. P4.

- Carlsson, D. J., Jensen, J. P., Wiles, D. M., Polym. Prep. (Am. Chem. Soc. Div. Polym.) 25 (1) (1984) 85.

- Zweifei H. Stabilization of polymeric materials. Berlin: Springer; 1997.

- Haoyi Yang. The antioxidant and light stabilizer for PE - LLD ultraviolet ageing stability [J]. China Plastic. Oct. 2011. Vol. 25, No. 10.

- Hans. Ciweifeier. Plastics Additives Handbook [M].

- Ministry of chemical industry synthetic material aging study. High polymer material aging and the aging [M]. Beijing: Chemical Industry Press, 1983.

- Gijsman P, Meijers G, Comparison of the UV-degradiation Chemistry of Polymer, Polyethylene, Polyamide 6 and Polybutylene Terephthalate [J]. Polymer Degradation Stability, 1999, 65: 433-441.

- Yuanyuan Tao. Light stabilizers and antioxidants on the properties of polyethylene aging effects [J]. Journal of Wuhan University of Technology. Aug. 2009. Vol. 31 No. 16.

- Taguchi Y, Ishid Y, Tsuge S, Ohtania H. Structural change of a polymeric hindered amine light stabilizer in polypropylene during UV-irradiation studied by reactive thermal desorption-gas chromatography [J]. Polymer Degradation and Stability. 2004, 83: 221-274.

(Xuejia Ding)

(Xuejia Ding)